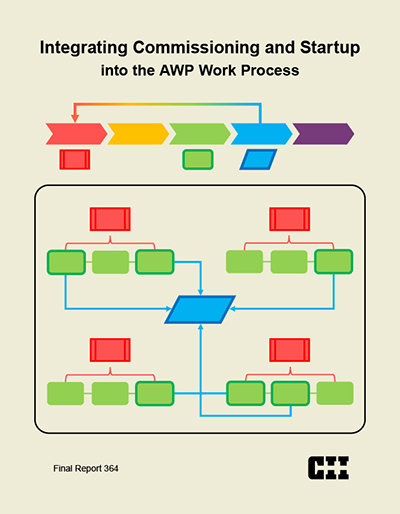

Integrating Commissioning and Startup into the AWP Work Process

Over the last decade, the emergence of Advanced Work Packaging (AWP) has prompted a fundamental rethinking of work execution management and related short interval planning. CII’s earliest research into AWP (RT-272, RT-319, and RT-TC-01) focused primarily on the engineering and construction phases. Concurrently, over the last six years CII researchers have completed significant research into commissioning (RT-121, RT-312, and RT-333). Collectively, these new insights present an opportunity to achieve a stepwise advancement in one of the most effective CII Best Practices: AWP. It has become apparent to CII that too often project teams celebrate completion of a project at construction completion, which is too early. Hence, the need to incorporate commissioning and startup (CSU) into the AWP framework to ensure that teams “begin with the end in mind” and only conclude the project when it produces a product, passes performance testing, and sustains production.

CII’s AWP scope-expansion research program covered these new AWP dimensions, and RT-364’s work focused exclusively on the CSU dimension. CSU input helps define the CSU sequences and the dependencies they have with Construction. It is also important to identify operating system and subsystem boundary definitions early, as these will also affect engineering, procurement, and construction milestones. Additional influences from CSU include turnover strategies, objectives, and constraints at the system and subsystem levels.

In order to achieve this vision of integrating CSU into AWP, RT-364 established and integrated a new type of work package within the AWP umbrella – the System Work Package (SWP) – primarily by adding a new swimlane to the integrated flowchart. An SWP is a deliverable that enables a commissioning work crew to perform work in a safe, predictable, measurable, and efficient manner. It should be scoped to be manageable and “progressable,” and it is typically scoped in a way that maps to existing commissioning zones, systems, subsystems, or subsystem components. It should also be mapped to predecessor installation work packages (IWPs) in order to ensure that the path of construction enables an efficient startup sequence. An SWP includes field/plant effort and is not the same as turnover documentation, which typically is only a collection of key documentation that facilitates the turnover of an asset from construction to commissioning.

In addition to introducing the SWP, the AWP/CSU research findings contained in this publication pertain to the following topics:

- The SWP effort scope and how it relates to the AWP hierarchy and IWPs

- Key SWP roles and responsibilities

- SWP constraints and model attribute data

- Brief real-world war stories of both success and failure at integrating CSU into AWP

This expanded model illustrates how the fundamental AWP principle of managing work package release via constraint monitoring can be extended beyond engineering/construction to include CSU. More importantly, this research demonstrates how early integration of CSU sequencing and priorities into the path of construction can help secure a more successful startup.

RT-364 identified the importance of CSU influences on the path of construction. The path of construction reflects diverse input drivers, including the project’s CSU strategy, objectives, and constraints (FR-364, p. 11).

RT-364 updated the original AWP flowchart to include an additional stage for “Energization and Commissioning.” The new AWP highlights the roles of Construction Work Packages (CWPs), Engineering Work Packages (EWPs), Installation Work Packages (IWPs), and System Work Packages (SWPs) (FR-364, p. 25).

RT-364 updated the AWP flowchart to integrate CSU into the four stages of the AWP process. The team inserted a new CSU swimlane and linked its activities to existing ones. The team also assigned new roles and responsibilities for each activity (FR-364, p. 35).

RT-364 identified the relationship between IWPs and SWPs and visualized it. IWPs are scoped and executed on an area basis, while SWPs are scoped and executed on a system, subsystem, or sub-subsystem basis (FR-364, p. 15).

Previous CII research outlined the constraint categories for developing IWPs. RT-364 identified additional categories of typical constraints relevant to SWPs (FR-364, p. 23).

To help clarify the meaning of the various SWPs, RT-364 developed a 3D illustration for each (FR-364, p. 17).

RT-364 expanded attribute data for piping (originally from RT-TC-01) by identifying additional CSU attributes that are required to effectively manage SWPs (FR-364, p. 24).